E-MAG P MODEL IGNITION LYCOMING

465 000

₽

Арт.

07-01292

Описание

Note: New installation requires a harness, and possibly a gear, depending on the application (See Accessories). Verify requirements before ordering. If you are replacing a NON-IMPULSE magneto you can re-use the manufacturer's ignition drive gear from the old magneto. If you are replacing an IMPULSE magneto, those gears are a different style and cannot be re-used with the E-Mag and a Lycoming (or Superior) gear must be purchased.

Lycoming 68C19622 gear: Part # 07-02011

Superior SL68C19622 gear: Part # 08-11837

Of all the E-MAG innovations, the self-powering capability of the "P" Model is the most significant. It solves the largest single issue faced by all electronic ignitions - their need for an uninterruptible power supply.

Power back-up strategies that a) compromise ignition effectiveness, b) solve only half the problem, or c) require additional maintenance are less than ideal. Next-Generation ignitions need a better solution. So what does a next-generation electrical back-up need to do?

Installing back-up batteries, together with switching circuits, to A) engage the back-up battery when needed, and possibly B) keep the back-up battery charged. This solution:

Lycoming 68C19622 gear: Part # 07-02011

Superior SL68C19622 gear: Part # 08-11837

Of all the E-MAG innovations, the self-powering capability of the "P" Model is the most significant. It solves the largest single issue faced by all electronic ignitions - their need for an uninterruptible power supply.

Power back-up strategies that a) compromise ignition effectiveness, b) solve only half the problem, or c) require additional maintenance are less than ideal. Next-Generation ignitions need a better solution. So what does a next-generation electrical back-up need to do?

- Above all, it has to be reliable. When it's needed, it has to work - period.

- It should operate for as long as needed. Whether it's the last 10 minutes of a Sunday pleasure flight, or you're crossing the Atlantic.

- It should be maintenance-free. Benign neglect should not prevent it from working.

- On the rare occasion it's needed, it should automatically engage without operator intervention.

- A simple and convenient pre-flight check should confirm it's working properly.

- This P model ignition has an internal three phase brushless alternator that produce enough power to sustain the ignition when the engine is turning 800 rpm, or more. If the aircraft buss voltage goes off-line, the ignition has an internal alternator. With this arrangement, dual electronic ignitions can be run "clean". No back-up batteries and no back-up magnetos.

The P Model Built-In Alternator

- Adds no (zero) mechanical contact/wear parts to the system

- Adds only a few ounces of weight

- Requires no additional hardware to install

- Will operate as long as the engine is turning

Installing back-up batteries, together with switching circuits, to A) engage the back-up battery when needed, and possibly B) keep the back-up battery charged. This solution:

- Adds wiring, switches, and batteries not part of the ignition kit typically provided by the manufacturer.

- Adds installation complexity.

- Adds maintenance.

- Offers a finite interval of back-up power.

- Offers marginal confidence insofar as batteries are not known for unquestioned reliability.

- Compromises the advantages of variable ignition timing and dual spark. Most of the time, mag timing (fixed) will fire before or after an electronic ignition using variable timing. Aircraft engines are designed for simultaneous firing from two plugs. Firing on one plug is not optimal.

- Compromises the maintenance advantage of electronic ignitions. The owner has the same inspection, maintenance, and cost components as before, albeit for one vs. two magnetos.

- Doesn't reduce the maintenance associated with magnetos. It adds what ever (minimal) attention is required for the electronic side.

- Doesn't eliminate underlying reliability issues associated with magnetos.

- Doesn't streamline the cost and complexity of the ignition package, as a whole. It makes it more complicated and much more expensive to produce.

- Requires spark plug gaps be set so magnetos are able to fire. A key advantage of electronic ignitions is the ability to increase spark plug gap to nearly double that of a magneto. You can't do that if your power back-up plan has the plug firing from a magneto.

Parts per assembly

Installation

Estimated Time: 2-4 Hours

1. Install Drive Gear: Recover the non-impulse drive gear from your old mag and install it on your E-MAG. If you don't have a suitable drive gear, E-MAG can provide one.

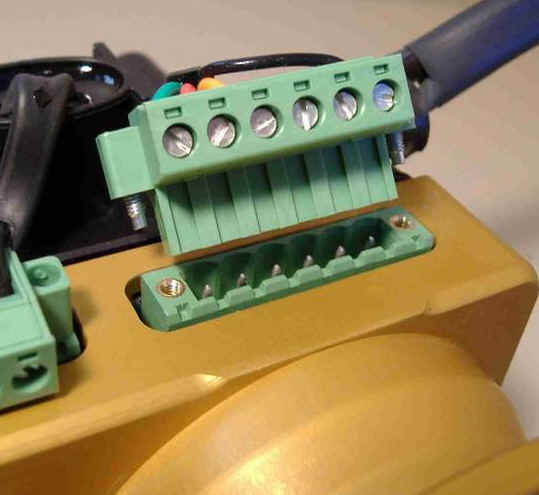

2. Connect Control Leads & Harness:

- Switch - Connect your existing ignition switch ("P Lead").

- Power - From your 12 volt power buss.

- Ground - Connect directly to engine case ground.

- Tach - (optional)

- MAP - Connect MAP sensor tube to fitting on ignition.

- Spark Plugs and Harness Kit

3. Install & Set Timing with Quick-Set TM:

- Pre-install the ignition(s) at any orientation that's convenient. You won't move them again so secure for operation. Position the engine at TDC.

- Power the ignition ON. Disconnect the MAP tubing where it ties into the craft and blow into it (minimum 1/2 psi for 1 second). The built-in LED will flash RED. Blow into the tube a second time and the LED will flash GREEN, indicating that timing has been set. Power cycle the ignition and your done.

Note: You can set timing on two E-MAGs in exactly the same way in exactly the same amount of time - 30 to 60 seconds.

Отзывы Оставить отзыв

Вопросы и ответы

Отзывы ещё не добавлены