TRUE-LOCK FASTENER SYSTEM STC FOR TWIN CESSNA

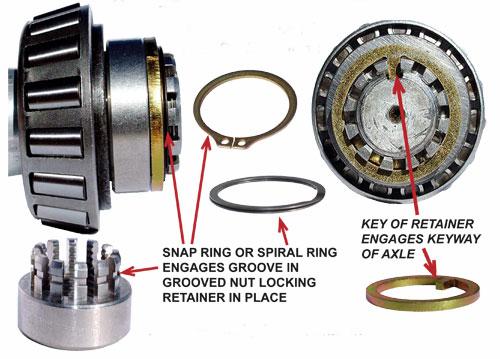

The True-Lock system eliminates the conventional axle nut system’s inherent inferior torque setting characteristics imposed by the castle nut and cotter pin (end-play).

True-Lock aviation fastener systems reduce premature wear on your wheel-end assembly parts (brakes, bearings, axles, including tires and wheels).

All True-Lock fastener systems are guaranteed for the life of your aircraft and pay for themselves over time by reducing downtime and fewer replacement parts. Eligibility

-

Twin Cessna aircraft models: 310, 310A(USAF U-3A), 310B, 310C, 310D, 310E(USAF U-3B), 310F, 310G, 310H, E310H, 310I, 310J, 310J-1, E310J, 310K, 310L, 310N, 310P, T310P, 310Q, T310Q, 310R, T310R, 321 (Navy OE-2), 320, 320-1, 320A, 320B, 320C, 320D, 320E, 320F, 335, 340, 340A, 401, 401A, 401B, 402, 402A, 402B, 402C, 411, 411A, 414, 414A, 421, 421A, 421B, 421C, 425

Mfg Q & A

Did you know?

The axle nut is the major culprit for failure within your wheel end components.

Bearing endplay is caused by axle nut torque that are set too loose.

Excessive bearing preload is caused by over tightening the axle nut.

TIMKEN has outlined acceptable endplay tolerances from 1 to 5 thousands of an inch. Most conventional axle nuts can not meet TIMKEN’s endplay tolerances for tapered roller bearings.

And, did you know?

True-ock’s fastener technology provides precise axle nut torque settings eliminating the conventional axle nut systems’ inherent torque setting limitations imposed by the castle nut and cotter pin.

True-Lock’s axle nut system is designed to achieve ultimate bearing adjustment and eliminating cotter pins; thereby improving bearing and axle longevity as well as enhancing tire and brake performance.

True-Lock systems are easy to install, reliable, reusable and maintenance free.

Отзывы ещё не добавлены